P&ID Symbols and Notation Lucidchart

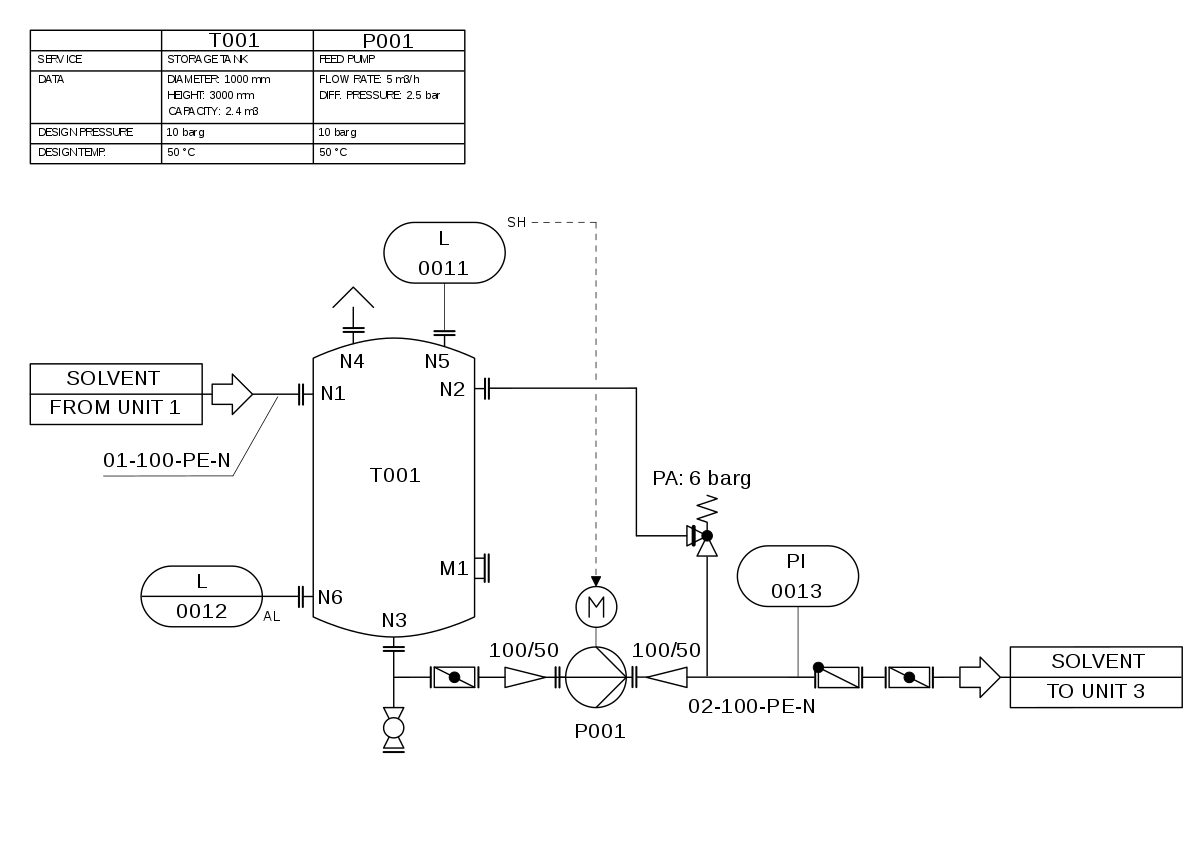

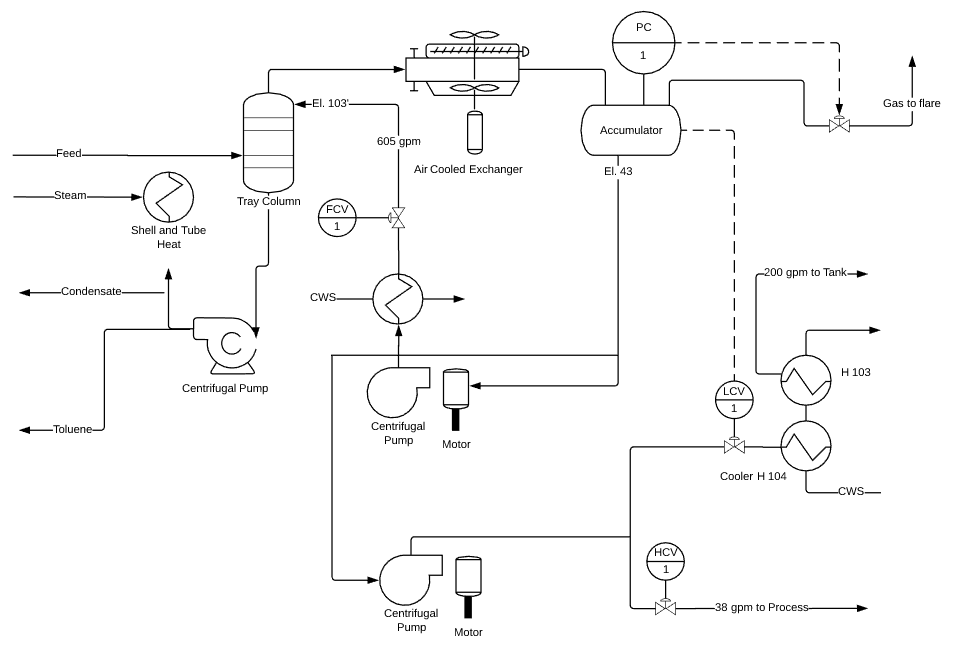

P&IDs, or Piping and Instrumentation Diagrams to give them their full name, are schematic representations of pipelines, equipment, instrumentation, and control systems found in process environments such as Oil Refineries, Chemical Plants, Paper Mills, and Cement Plants, etc. P&ID Symbols and Codes

Piping and Instrumentation Diagram Tool

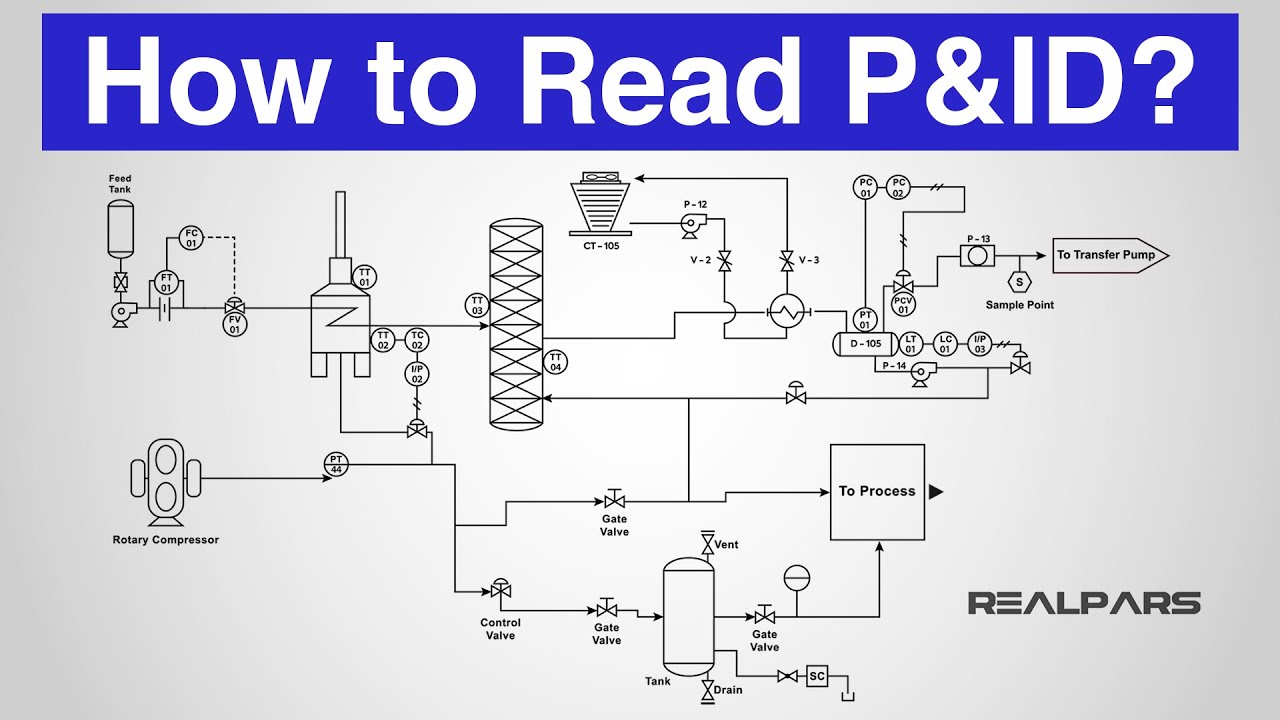

A piping and instrumentation diagram (P&ID) is defined as follows: A diagram which shows the interconnection of process equipment and the instrumentation used to control the process. In the process industry, a standard set of symbols is used to prepare drawings of processes.

P & ID Diagram. How To Read P&ID Drawing Easily. Piping & Instrumentation Diagram Explained

A Process and Instrumentation Diagram (P & ID) shows the process flow and interconnection of process equipment which is used control a process. The P & ID includes every mechanical aspect of the plant except stream flows, pipe routing, pipe lengths, pipe fittings, supports, structure & foundations.

How to Read and Interpret Piping and Instrumentation Diagrams (P&ID) Learning Instrumentation

The P&ID diagram software comes with a rich set of high-quality P&ID symbols for you to create different kinds of P&ID diagrams. Without a doubt, Visual Paradigm Online is the best P&ID software to create schematics for the process industry. With Visual Paradigm Online, you don't need to start each P&ID from scratch because a rich set of piping.

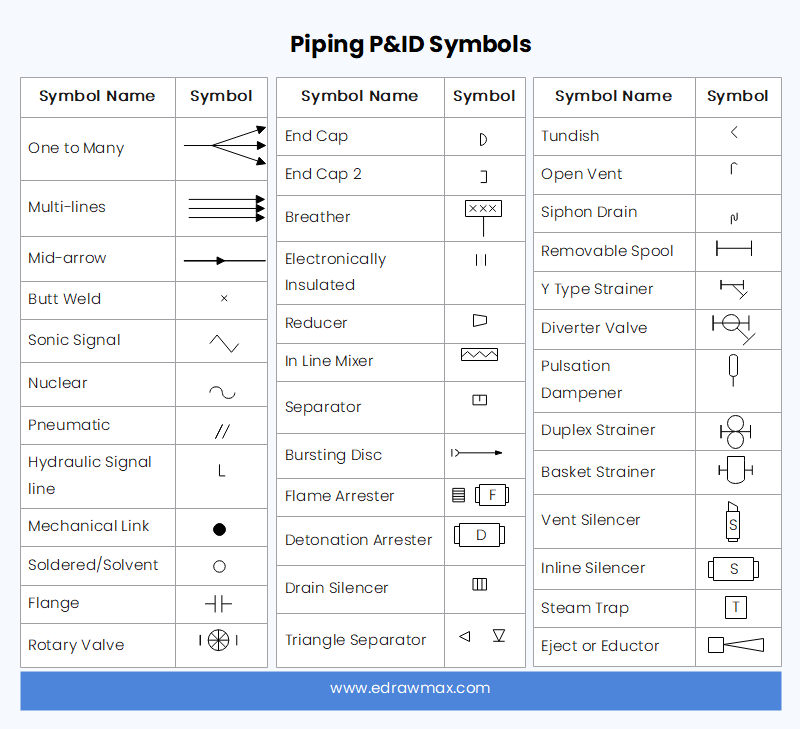

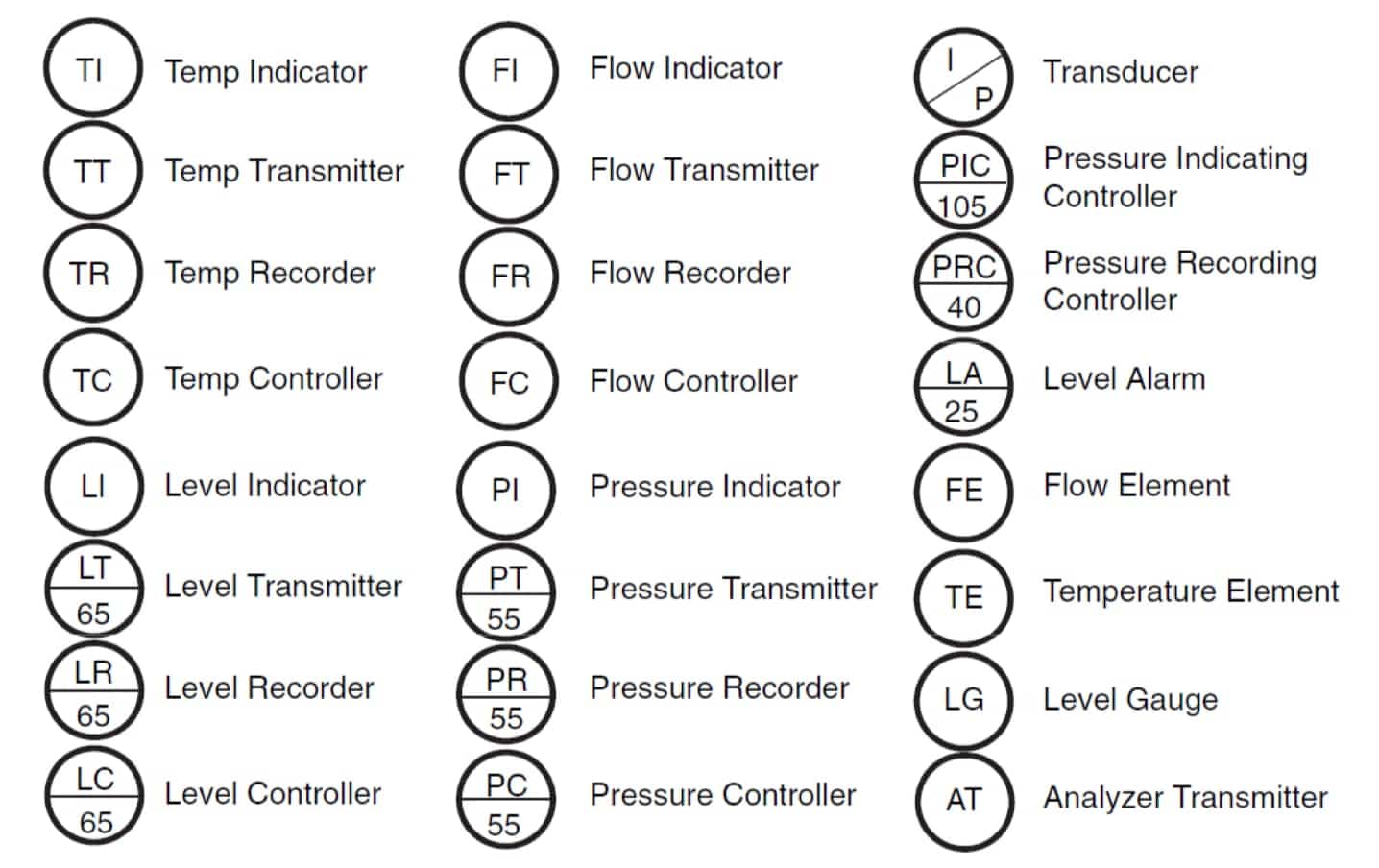

P&ID Symbols and Meanings EdrawMax Online

1. What is P&ID? Abbreviated as P&ID, a piping and instrumentation diagram is an articulate drawing of a processing plan that entails the piping and process equipment with its instrumentation and control machinery. It displays the piping and associated parts of a physical process flow. Such diagrams are famous in the engineering field.

P&ID Symbols and Meanings EdrawMax Online

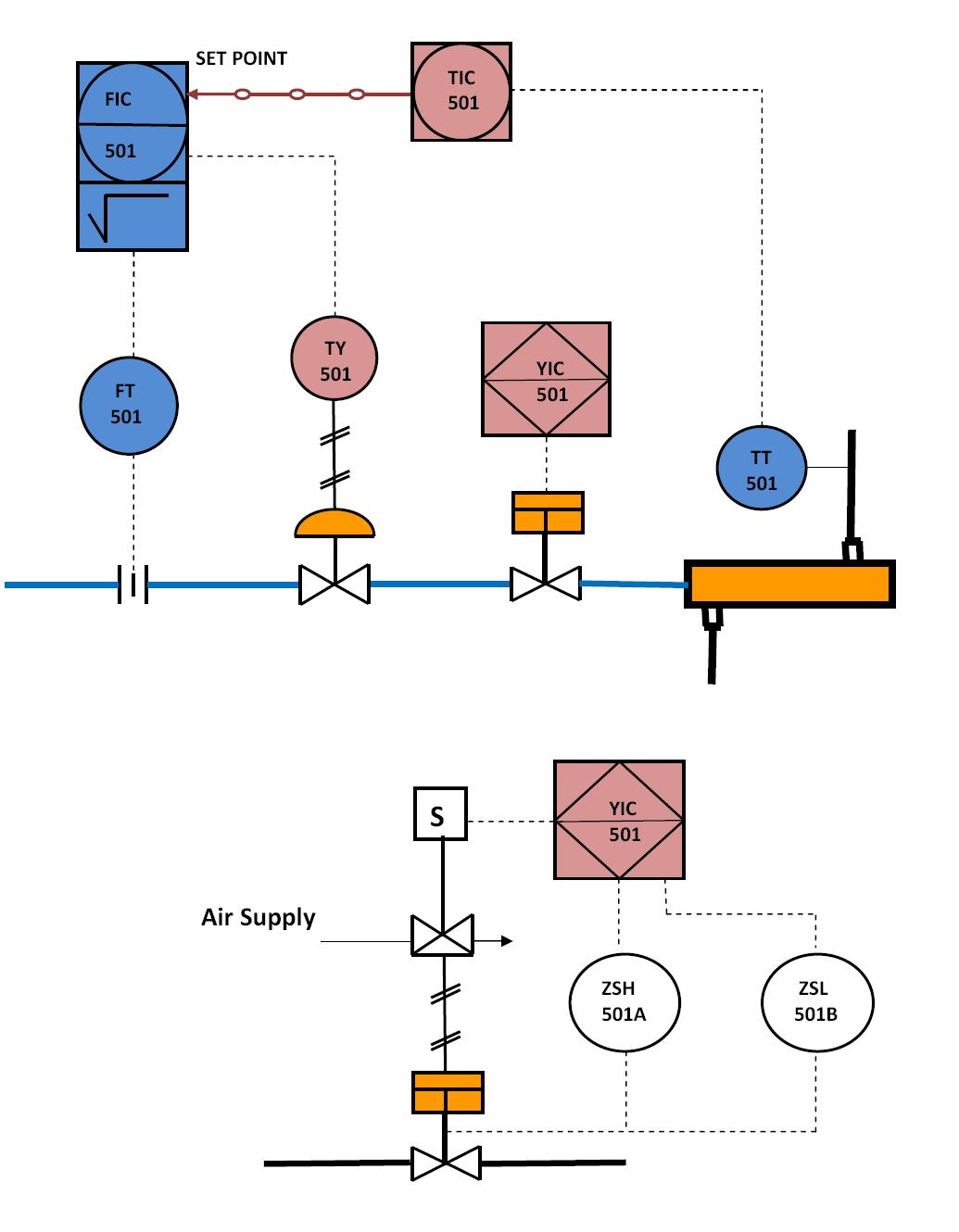

A Piping & Instrumentation Diagram (P&ID) is a schematic layout of a plant that displays the units to be used, the pipes connecting these units, and the sensors and control valves.. Figure D is a representation of a control scheme that could be implemented. This is the reverse of the control scheme in Figure 6. Figure 7. Liquid-liquid.

P&ID Symbol Diagram Basics 3/3 Functional Identification and Naming Conventions (2022)

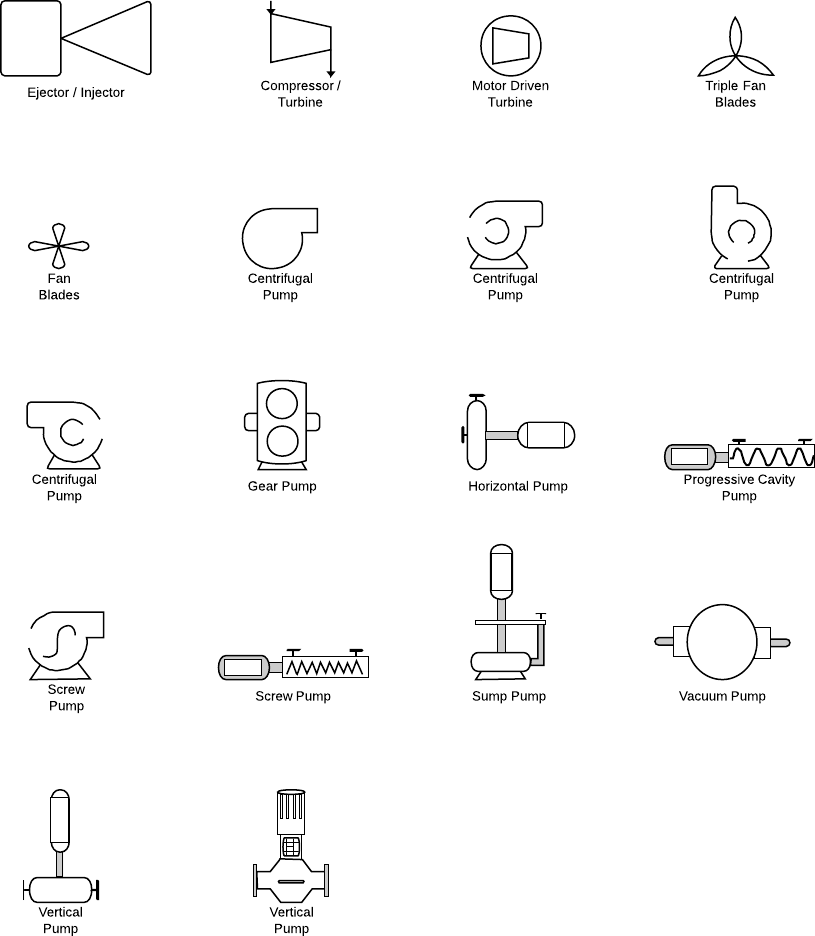

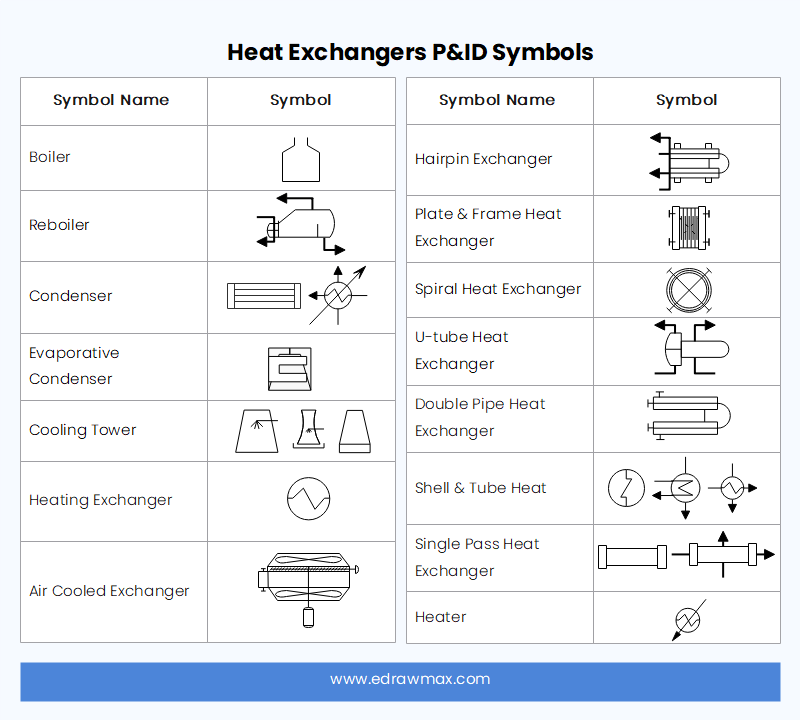

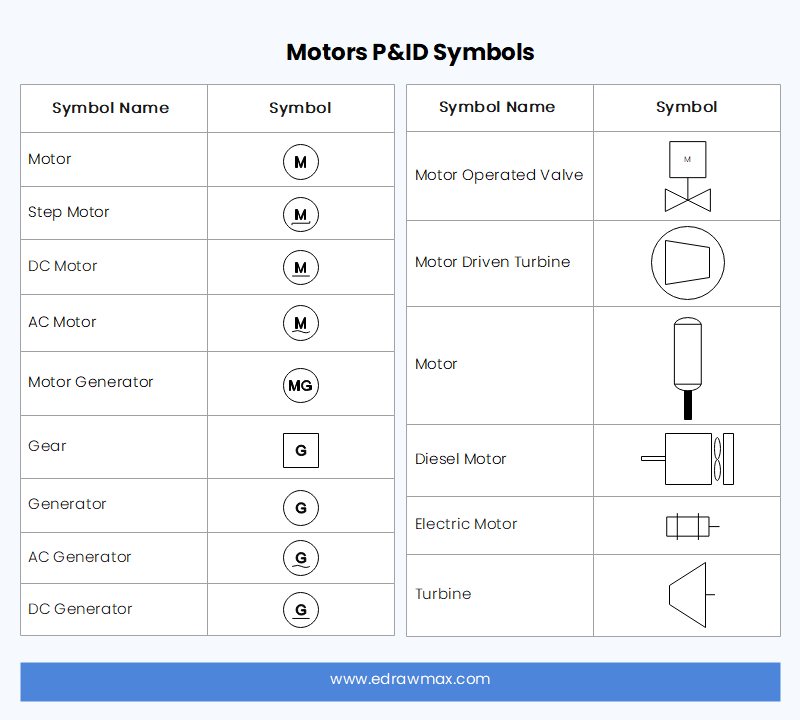

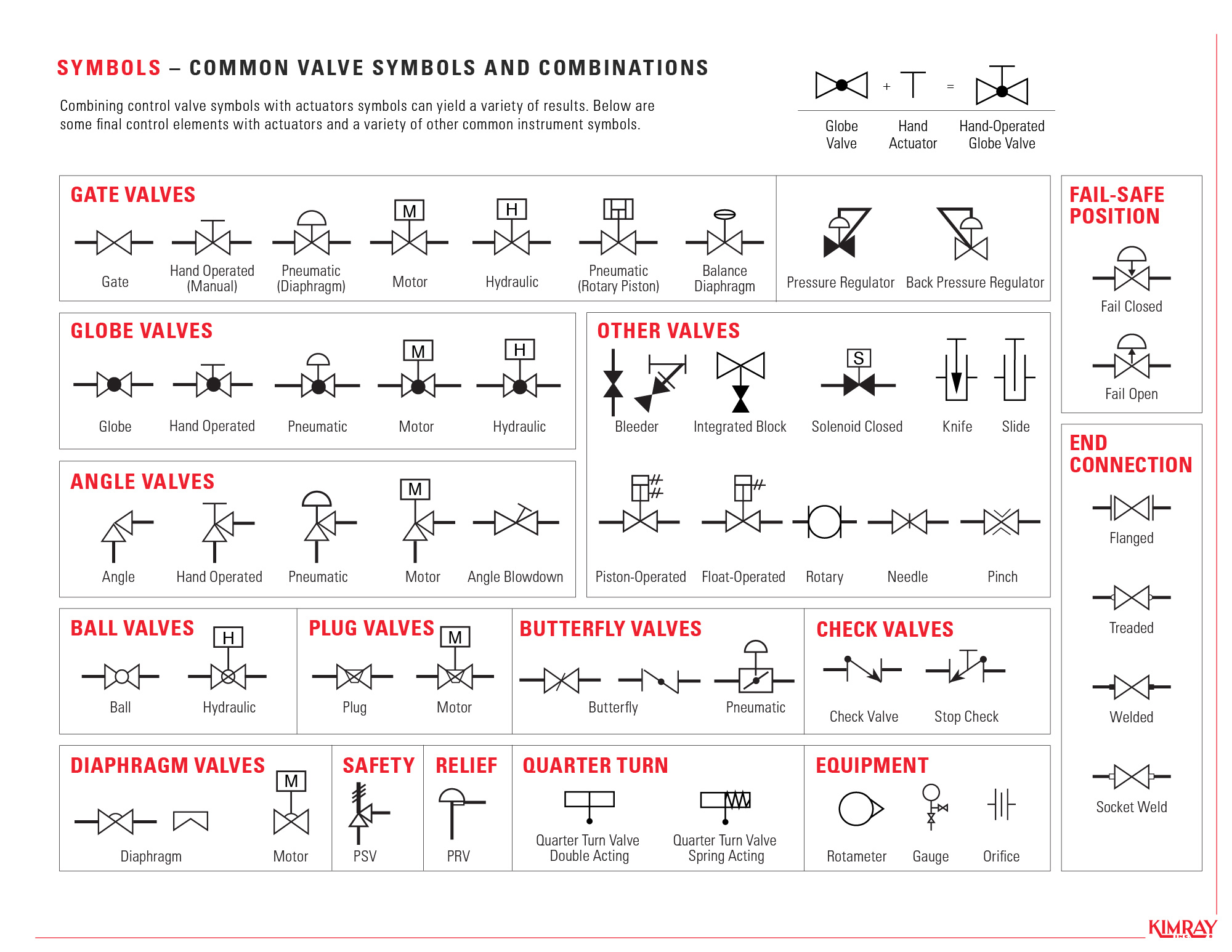

Piping and Instrument Diagram Standard Symbols Detailed Documentation provides a standard set of shapes & symbols for documenting P&ID and PFD, including standard shapes of instrument, valves, pump, heating exchanges, mixers, crushers, vessels, compressors, filters, motors and connecting shapes. Or Gate Not Gate Correcting Element Diamond

Piping and Instrumentation Diagram P&ID Chemical Engineering Site

The PID-controller output will be a combination of the P-only, I-only and D-only controller outputs. Analogous to the P-controller output for the step input, the P-controller output for the pulse input will exactly resemble the input. Figure 9. P-controller output for pulse input. The I-controller output represents the area under the input graph.

P&ID Document Reading Example Instrumentation Tools

December 21, 2017. A piping and instrumentation diagram (P&ID) is a graphic representation of a process system that includes the piping, vessels, control valves, instrumentation, and other process components and equipment in the system. The P&ID is the primary schematic drawing used for laying out a process control system's installation.

Qué es un P&ID Guía para principiantes

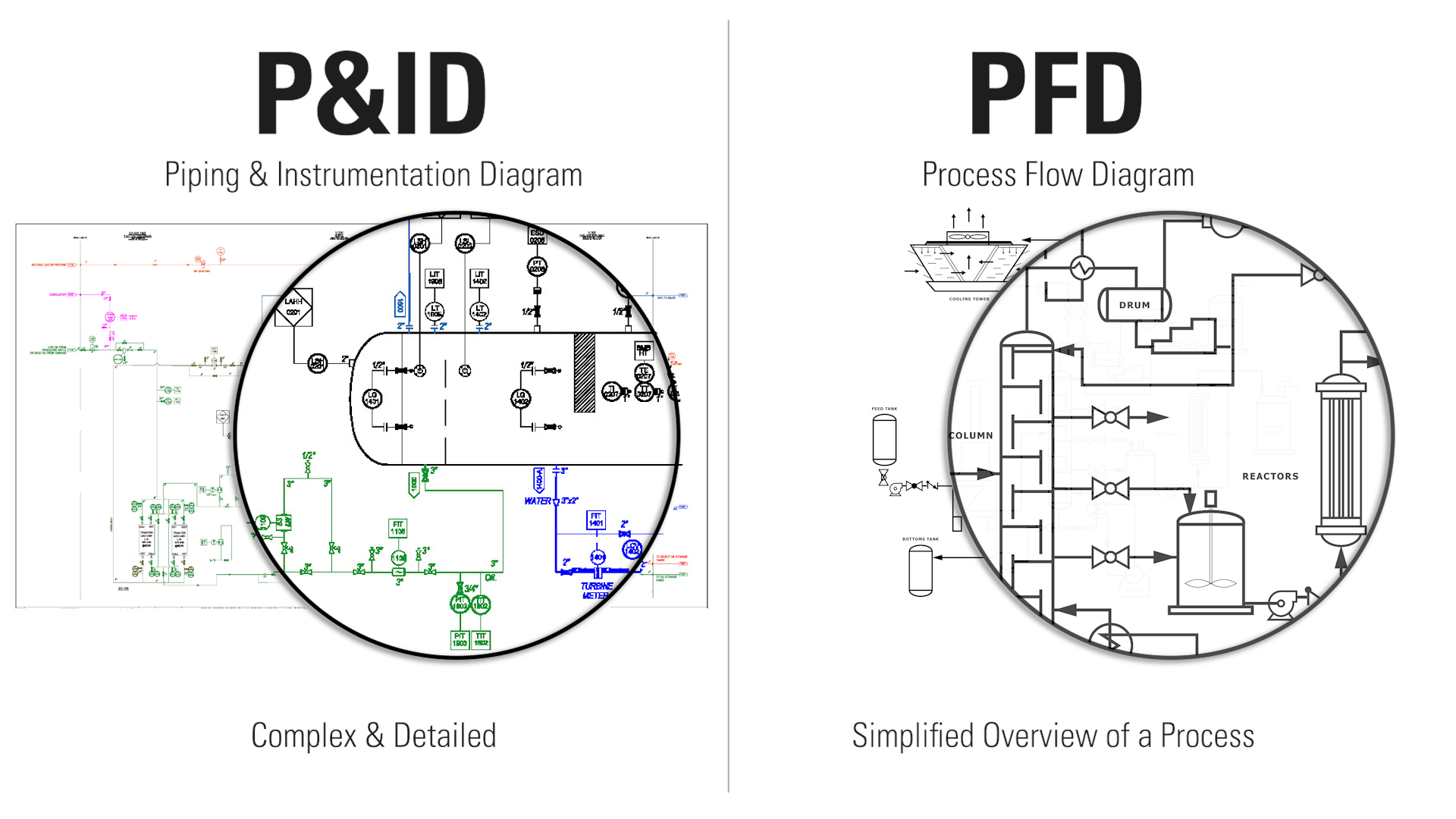

P&ID is a graphical representation of the actual process plant using various symbols that represent actual equipment. As said earlier, it is more complex than PFD. A single PFD can have multiple P&IDs. This means if some system is shown on a single PFD, it may require multiple P&ID sheets to show the same system on P&ID.

P&ID Symbols and Meanings EdrawMax Online

P&IDs are a schematic illustration of the functional relationship of piping, instrumentation and system equipment components used in the field of instrumentation and control or automation. They are typically created by engineers who are designing a manufacturing process for a physical plant.

How to Read a P&ID? (Piping & Instrumentation Diagram) YouTube

Sales personnel and OEMs (original equipment manufacturers) use P&IDs to spec equipment and build the vessels. Not all P&ID elements are standardized, but the instrumentation symbols follow a standard set by the International Society of Automation (ISA). The ANSI/ISA's S5.1 standards are what this guide will be using to communicate consistently.

Instrumentation Today HOW TO READ A P&ID

Piping and Instrumentation Diagrams (P&IDs) use specific symbols to show the connectivity of equipment, sensors, and valves in a control system. These symbols can represent actuators, sensors, and controllers and may be apparent in most, if not all, system diagrams. P&IDs provide more detail than a process flow diagram with the exception of the.

Instrumentation Today HOW TO READ A P&ID

A proportional-integral-derivative controller ( PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuously modulated control.

How to Read Oil and Gas P&ID Symbols Kimray

Easy Piping and Instrumentation Diagram Software Create professional industrial diagrams including P&ID Create Your P&ID Diagram The Easy Choice for Creating Your P&ID Online More Than Just Piping & Instrumentation Diagrams SmartDraw is much more than P&ID software.

How to Read Oil and Gas P&ID Symbols Kimray

A piping and instrumentation diagram displays the piping components (for example equipment, valves, reducers and so on) of an actual physical process flow and is often used in the engineering projects, such as setting up steam boilers, heat exchangers, electric boilers and more. To read a piping and instrumentation diagram, simply break down.